Description

The standard series IMCB double row angular contact ball bearings  include:

include:

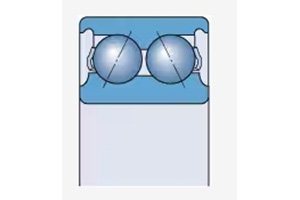

Bearings of 32 A and 33 A series

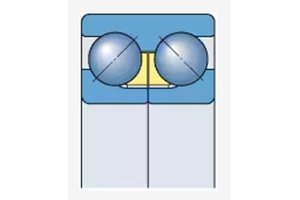

33 D series bearings:

closed bearing

Open type bearings (with closed type) have grooves on the outer ring side.

52 and 53 series bearings are no longer available and have been replaced by 32 A and 33 A series bearings that are interchangeable in size. The only difference is the size 3200 A, which has a width of 14 mm instead of 14.3 mm.

Bearings with double half inner rings

It can accommodate more steel balls and has a larger contact angle, so the bearing has higher load-bearing capacity, especially axial load-bearing capacity

In the 33D series, it belongs to the separable design , which means that the outer ring component with steel balls and retainers can be independently installed from the double half inner ring

, which means that the outer ring component with steel balls and retainers can be independently installed from the double half inner ring

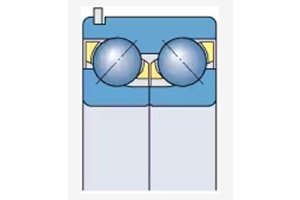

It belongs to the inseparable design in the 33 DNRCBM series

A stop ring is installed in the stop groove of the outer ring, making axial positioning in the bearing seat both simple and space saving.

It is specifically designed for centrifugal pumps, but is also suitable for other applications

closed bearing

IMCB offers the most commonly used basic model bearings with sealed or dust-proof covers on both sides, as well as IMCB Explorer bearings. For more information, please refer to the built-in seal.

dust cover

Represented by model suffix 2Z

Made of stamped steel

Extend into the groove on the inner ring

Contact seal

Represented by the suffix 2RS1

Made of nitrile rubber

Reinforced with steel frame

Installed in the groove on the outer ring and in direct and tight contact with the groove on the inner ring

The sealing lip applies slight pressure to the inner groove to form an effective seal.

When closed bearings must operate under extreme conditions such as extremely high speeds or temperatures, grease leakage may occur between the inner ring and seal. If the leakage will have adverse effects on the bearing configuration, corresponding measures must be taken

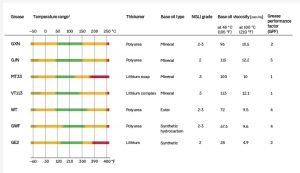

Lubricating grease for closed bearings

The bearings sealed on both sides adopt lifelong lubrication, which can achieve maintenance free. The closed bearing is pre filled with the following type of grease :

Standard lubricating grease → GJN

In Europe → MT33 (commonly used and widely available)

Low friction grease → GE2

Other lubricating greases can be provided upon request

Standard lubricating grease will not be labeled in the bearing model (without suffix). Other lubricating greases are indicated by their corresponding grease suffixes.

Lubricating grease life of closed bearings

Represented by L10, at the end of this time period, 90% of the bearings can still receive reliable lubrication

Depending on:

operation temperature

Speed coefficient ndmm value

The coefficient of performance (GPF) of lubricating grease is shown in Table 1

The above-mentioned grease life is applicable under the following working conditions:

horizontal axis

Inner circle rotation

Light load (P ≤ 0.05 C)

The working temperature is within the green temperature range of the grease traffic light concept Table 1

Non mobile devices

Low vibration level

If the operating conditions are different from the following conditions, the lubricant life obtained from the chart needs to be adjusted:

Vertical axis → 50% of the obtained value

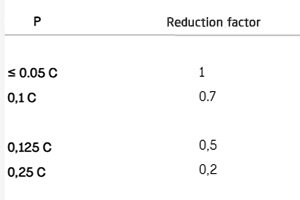

For heavier loads (P>0.05 C) → use the reduction factor in