Description

IMCB self-aligning ball bearing variant:

Open type bearing ( )

)

With cylindrical hole

With a conical hole, it can be used together with a tightening sleeve ( )

)

Extended Inner Ring Bearing ( )

)

Sealed bearings ( )

)

With cylindrical hole

With a conical hole, it can be used together with a tightening sleeve

sealed bearing

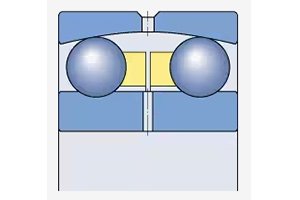

Sealed bearings with contact seals on both sides can be provided ( ):

):

Series 22 and 23

Inner diameter 10 ≤ d ≤ 70 mm

Nitrile rubber seal with steel frame (oil resistant, wear-resistant, model suffix 2RS1)

Compared to open type bearings, sealed bearings allow for a reduced misalignment angle.

Lubricating grease for sealed bearings

The bearings with seals on both sides can provide lifelong lubrication and are almost maintenance free. The bearing is pre filled with the following standard lubricating grease, which has good corrosion resistance characteristics:

D ≤ 62 → MT47 lubricating grease

D ≤ 62 → MT33 lubricating grease

Lubricating grease life of sealed bearings

Represented by L10, it means that at the end of this time period, 90% of the bearings still have reliable lubrication

Depends on the working temperature and speed coefficient

The lifespan of the lubricating grease in Figure 1 is obtained by considering the following operating conditions:

horizontal axis

Inner circle rotation

Light load (P ≤ 0.05 C)

The working temperature is within the green temperature range of the lubricating grease

Non mobile devices

Low vibration level

If the working conditions are different, it is necessary to adjust the grease life obtained from the chart:

Vertical axis → 50% of the value obtained in the figure

For heavier loads (P>0.05 C) → please use the listed reduction factor

When sealed bearings must operate under extreme conditions such as extremely high speeds or temperatures, grease leakage may occur on the inner ring. If the leakage situation will have a damaging impact on the bearing configuration, effective measures must be taken. For more information, please contact the IMCB Application Engineering Services department.

Large self-aligning ball bearings

130 and 139 series are available

There is an annular lubrication groove on the outer ring ( ), and:

), and:

There are three equally spaced lubrication holes on the outer ring

There are six evenly spaced lubrication holes on the inner ring

Can be used in any application that requires low friction and high load-bearing capacity (such as in the paper industry)

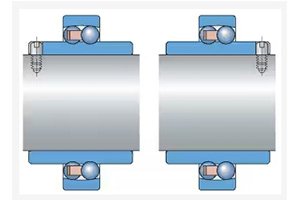

Extended Inner Ring Bearing

Designed for commercial grade shaft applications with less stringent requirements

Its inner diameter adopts a special tolerance grade JS7 (Table 3) for easy installation and disassembly

Use the locating pin or fastening screw installed in the groove on one side of the inner ring to perform axial positioning on the shaft ( )

)

This can prevent the inner ring from rotating on the shaft.

Holder

According to different bearing series or sizes, IMCB self-aligning ball bearings are equipped with a cage listed in Table 4.

When used at high temperatures, some lubricants may have adverse effects on nylon retainers. For more information on the applicability of the cage, please refer to the cage.