As a core transmission component of precision machinery, rotary cross roller bearings are widely used in scenarios such as robot joints, CNC turntables, and automation equipment, thanks to their advantages of high rigidity, high precision, and low friction. However, most purchasers and engineers often encounter problems in selection, installation, and maintenance, resulting in substandard precision or much shorter service life than expected. Based on years of industrial supporting experience, this article breaks down practical details from product characteristics, selection points, scenario adaptation to maintenance skills, helping you avoid misunderstandings and improve equipment operation stability.

I. Core Product Characteristics: Why Are They the First Choice for Precision Scenarios?

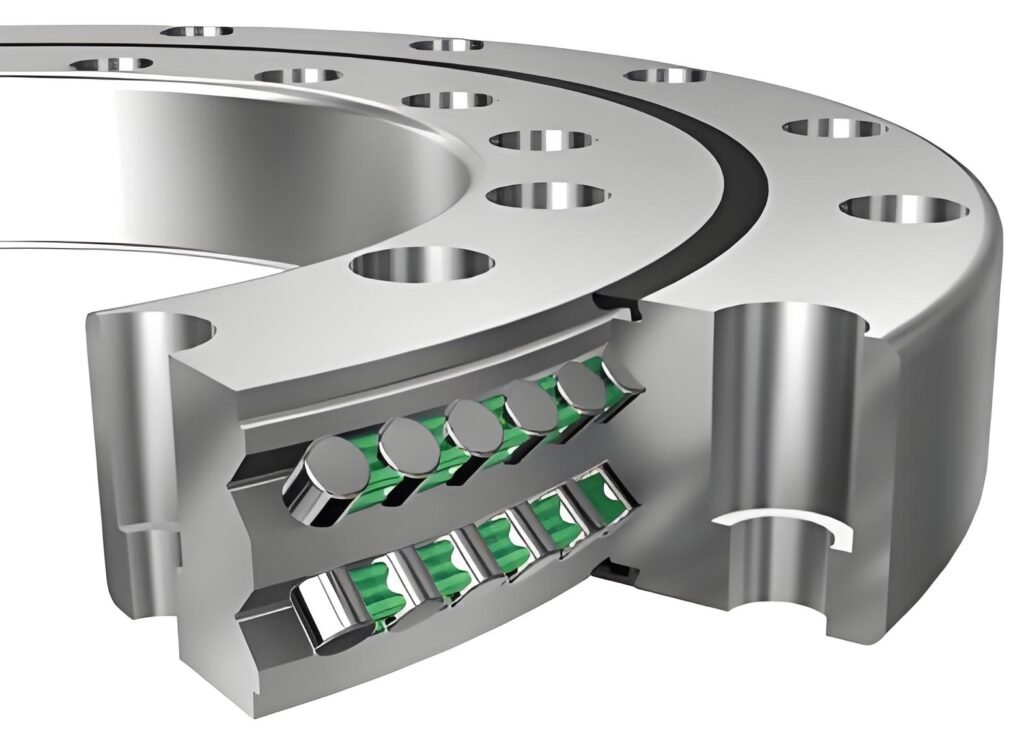

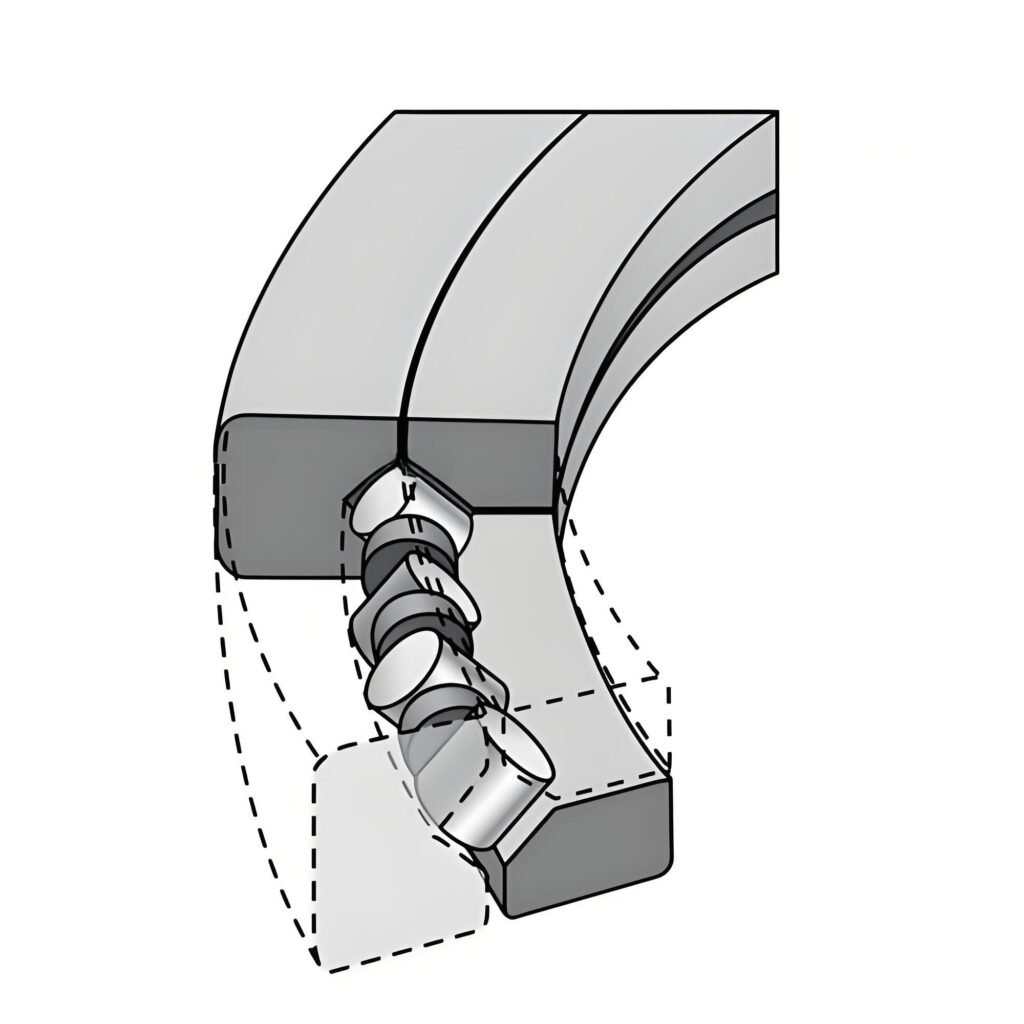

The core advantages of rotary cross roller bearings stem from their unique structural design—rollers are arranged crosswise at 90° between the raceways of the inner and outer rings, and precisely positioned by cages. Compared with ordinary bearings, they have three irreplaceable characteristics.

First, the coexistence of high rigidity and high precision. The rollers are in line contact with the raceways, with a large contact area, capable of bearing combined loads such as radial, axial, and tilting moments. Their rigidity is more than 40% higher than that of deep groove ball bearings, and the precision can be stably controlled within 0.001mm, fully meeting the strict requirements for positioning accuracy of robot joints, precision turntables, and other components. Second, low friction and high stability. The precision-ground raceways and rollers achieve a friction coefficient as low as 0.0015, ensuring no obvious vibration during operation. Moreover, the sealing structure can be customized on demand, effectively resisting the intrusion of dust and cutting fluid, and adapting to complex industrial working conditions. Third, compact structure and space-saving installation. The integrated design eliminates the need for additional positioning components, reducing the installation size by 20% compared with self-aligning roller bearings of the same specification, making them particularly suitable for the transmission mechanisms of small automation equipment.

It should be noted that the quality of bearings on the market varies. High-quality products are made of GCr15 bearing steel or stainless steel, and after carburizing and quenching, their hardness can reach HRC60-64. In contrast, inferior products mostly use ordinary steel, which is prone to roller wear, raceway deformation, and other issues. Therefore, it is crucial to verify the material inspection report when purchasing.

II. Core Selection Points: Avoid 3 Common Misunderstandings

Selection is the key to determining the service life of bearings. Many people only select bearings based on size matching, ignoring core factors such as load, speed, and working conditions, leading to frequent failures later. Based on practical experience, selection must focus on 4 dimensions and avoid three misunderstandings:

First, clarify the load type and magnitude, and avoid the “one-size-fits-all” misunderstanding. The load characteristics vary greatly in different scenarios—for example, robot joints mainly bear tilting moments, while CNC turntables mainly bear radial loads, so bearing types should be selected accordingly. For combined loads, models with integrated seats are preferred; for axial loads, ultra-thin cross roller bearings can be used. Meanwhile, a 10-15% load margin should be reserved to prevent deformation caused by overloading.

Second, match precision grade and speed, and avoid the “higher precision the better” misunderstanding. Precision grades (P0-P2) should be selected according to equipment requirements: P0 grade is sufficient for ordinary automation equipment, while P2 grade is required for precision CNC turntables and robot joints. In terms of speed, refer to the bearing’s limit speed, and control the actual operating speed within 70% of the limit speed. If the speed is too high, optimize the lubrication scheme to prevent excessive temperature rise from affecting precision.

Third, adapt to working conditions, and avoid the “universal model” misunderstanding. For humid and dusty environments, select double-sealed bearings with anti-rust treatment, and prioritize nitrile rubber or fluororubber for sealing materials; for high-temperature working conditions (above 120℃), use high-temperature resistant grease and adjust the bearing clearance accordingly; for corrosive environments, directly select stainless steel materials to avoid material oxidation affecting performance.

In addition, carefully check the model marking. For example, for “Rotary Cross Roller Bearing 200x300x40mm”, confirm the inner diameter, outer diameter, width, and mounting hole dimensions. If necessary, request samples from the manufacturer for test installation to avoid assembly difficulties caused by dimensional deviations.

III. Mainstream Application Scenarios: Targeted Adaptation Skills

Although rotary cross roller bearings are widely used, the adaptation logic varies in different scenarios. It is necessary to optimize selection and installation according to equipment characteristics. The following practical skills for 3 core scenarios can be directly applied:

Robot joint scenario: Focus on tilting moment and precision, prefer ultra-thin cross roller bearings with precision grade P2 or above. Adopt interference fit during installation and fix with positioning pins to avoid displacement during operation. We once customized robot joint bearings for a German automation enterprise, controlling the precision within 0.0008mm, which solved the vibration problem of their equipment during high-speed operation, with zero complaints in 18 months of mass supply. The core lies in accurately matching the tilting moment requirements and installation method.

CNC turntable scenario: Focus on radial load and speed, select high-rigidity bearings with seats. Ensure the flatness error of the bearing seat is ≤0.002mm during installation, and regularly check the lubrication status to prevent cutting fluid from invading the raceways. Practical experience shows that bearings with proper sealing and lubrication can have their service life extended by more than 30%.

Medical equipment scenario: Prefer stainless steel materials + sterile grease. The bearing surface should be passivated to avoid rust pollution in the medical environment, and low-noise operation is required (noise level ≤35dB) to adapt to the silent demand of medical instruments.

IV. Daily Maintenance Points: Key Actions to Extend Service Life

Most bearing failures are caused by improper maintenance rather than quality issues. Doing the following 3 points well can effectively extend the service life:

First, regular cleaning and lubrication. Clean the bearing raceways with anhydrous ethanol every month, avoiding corrosive cleaning agents. After cleaning, apply lithium-based grease, and control the dosage to 1/3 of the raceway gap—excessive or insufficient dosage will affect operation performance. For high-temperature working conditions, check the lubrication status every two weeks and supplement high-temperature resistant grease in a timely manner.

Second, regular detection of operating status. Monitor the bearing’s operating vibration value with a vibration detector. If the vibration value exceeds the standard range (usually ≤2.5mm/s), timely check for roller wear, raceway deformation, and other problems. Meanwhile, monitor the bearing temperature rise—the normal temperature rise during operation should be ≤40℃; if exceeded, stop the machine for inspection.

Third, good installation protection. Avoid violent knocking during assembly, use special tools for uniform pressure application to prevent damage to rollers or raceways. After the equipment is shut down, promptly clean dust and cutting fluid on the bearing surface to avoid corrosion caused by long-term accumulation, and apply anti-rust oil for protection when idle.