Description

IMCB provides the following basic and application specific design and manufacturing standard versions of tapered roller thrust bearings:

Unidirectional tapered roller thrust bearing

Bidirectional tapered roller thrust bearing

Screw fastening bearings

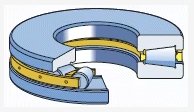

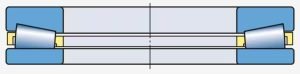

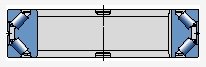

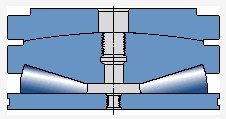

Unidirectional tapered roller thrust bearing

Provide symmetrical

or asymmetrical

versions relative to the shaft and bearing seat washers

Symmetrical form :

Shaft and bearing seat washers with the same design, featuring tapered raceways and a guide edge

Often used in applications that require significant axial loads, such as drilling equipment turntables or top drives, or crane hooks

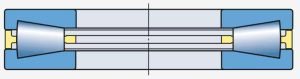

Asymmetric form :

The shaft washer has a tapered raceway and guide edge, while the seat ring has a flat raceway

Longer rollers can be installed, so compared to symmetrical forms of the same size, they can withstand higher axial loads

Can compensate for the smaller eccentricity of the shaft relative to the bearing seat hole

Equipped with roller guide cage

Provide several types, such as using different bearing seat washers and covers

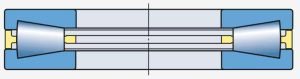

Small unidirectional tapered roller thrust bearing

Almost exclusively used for the arrangement of main bearings in commercial vehicles

Provide fully loaded roller bearings, fixed with thin steel plate covers .

Wear resistant and oil resistant NBR seals

can be used, and multi-purpose grease can be used for lifelong lubrication

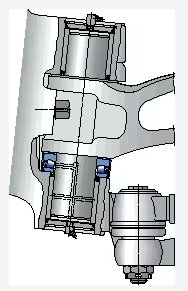

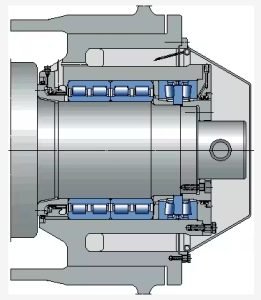

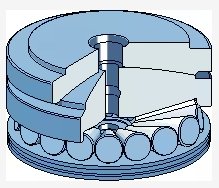

Large unidirectional tapered roller thrust bearing (product list)

Mainly used for top drive systems in the oil and gas industry

Designed to improve the reliability of top drive, extend its service life, and achieve high load-bearing capacity

It’s IMCB Explorer bearings

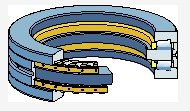

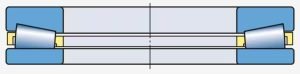

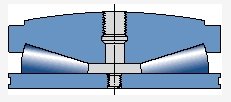

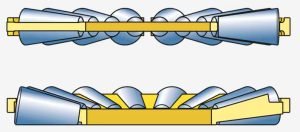

Bidirectional tapered roller thrust bearing

Mainly used together with double row cylindrical roller bearings or four row cylindrical roller bearings in rolling mill applications

Provide versions with flat shaft washers

or tapered raceways on the shaft and washers

Type with flat shaft washer :

Can compensate for the smaller eccentricity of the shaft relative to the bearing seat hole – for example, the internal clearance of the radial bearing (Figure 10)

There is a spacer between the two bearing seat washers, designed to allow the end cap screws of the bearing seat to be fully tightened without the need for springs

The type with conical raceway on two washers:

Compared to bearings with flat shaft washers, they typically have higher axial load-bearing capacity

Capable of radial positioning of the shaft to a certain extent

A shaft washer with one or two positioning slots can be provided to prevent the shaft washer from rotating on its seat, as bearings are usually installed with clearance fit in the roll neck and in the bearing seat

If the load-bearing capacity of the bi-directional tapered roller thrust bearing is insufficient, an alternative solution to the TDIS design is to use double row tapered roller bearings with higher contact angles.

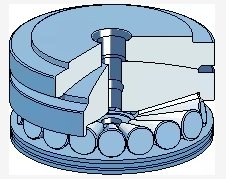

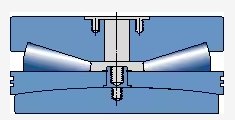

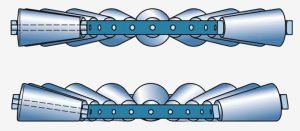

Press down the bearing

Almost exclusively used for screw fastening applications in rolling mills

It is a special design of unidirectional tapered roller thrust bearing

Can be customized according to customer requirements

To fully accommodate the rolling body type, there are ultra long large-diameter rollers

Capable of withstanding extremely heavy axial loads

By keeping the components firmly together through special means

A washer with threaded holes, used for eye bolts to simplify handling

Can compensate for the angular motion of the screw spindle relative to its supporting components

The centering motion of the bearing seat can be carried without harmful effects on the bearing performance by using spherical shaft washers

or spherical bearing seat washers

Spherical shaft washer:

The centering motion is carried above the roller complementarity between the spherical shaft washer and the corresponding concave spherical threaded spindle or pressure plate.

Spherical bearing seat gasket:

The centering offset is supported by the roller group between the seat ring and the pressure plate.

IMCB also provides suitable pressure plates

Holder

IMCB tapered roller thrust bearings without fully loaded rollers are equipped with one (one-way bearing) or two (two-way bearing) retainers as follows:

Machine cut brass retainer

Pillar type steel cage (perforated roller,)

Window type stamped steel retaining frame

![]()