Description

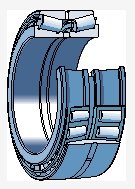

There is a double row outer ring (double raceway outer ring) and two inner rings with rollers and cage components (cones), usually with a spacer between the two inner rings

There are several rows of rollers arranged back-to-back (with the load line separated from the axis of the bearing) to provide a highly rigid bearing arrangement and withstand significant overturning moments

It is a quick installation unit with preset axial clearance or preload during manufacturing

Can be used as a positioning end bearing or a floating end bearing:

For floating end bearings, axial displacement should occur between the outer ring and the bearing seat hole

Bearings with blind holes or positioning grooves on the outer ring can be fitted with cylindrical pins to prevent the outer ring from rotating on its base

IMCB has manufactured various types (types/characteristics) of TDO type bearings, such as:

Design form characteristics

TDO

There is a spacer between the two inner rings

Window steel retaining frame

TDO.1

There is a spacer between the two inner rings

Pillar type steel cage (perforated roller) suitable for higher loads

TDON

No spacer ring

The interdependent inner circle

Window steel retaining frame

TDO/Z

There is a spacer between the two inner rings

Window steel retaining frame

Steel plate dust covers on both sides

TDOS.1

Large contact angle α

Suitable for applications where high axial loads or high overturning moments occur together with radial loads

There is a spacer between the two inner rings

Pillar type steel cage (perforated roller) suitable for higher loads

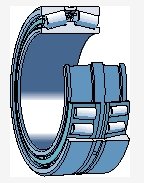

TDI type bearings

There are two outer rings (cup-shaped) and a double row inner ring with two rollers and a cage assembly (double cone), usually with a spacer between the two outer rings

There are several rows of rollers arranged face to face (load lines converge towards the axis of the bearing)

Open or with dust cover or seal

Both sides are equipped with HNBR or FKM contact seals

It is a quick installation unit with preset axial clearance or preload during manufacturing

Mainly designed for use as a fixed end bearing

Optional holes with spiral grooves and/or lubrication grooves on the side of the bearing ring

When loose fit is required on the shaft, these slots will compensate for the disadvantage of loose fit

When the inner ring rotates under load on its support, these grease lubricated grooves can supply lubricant between the inner ring and the support surface

In addition, these grooves can also absorb wear particles

IMCB has manufactured various types (types/characteristics) of TDI type bearings, such as:

Design form characteristics

TDI

The spacer between two outer rings

Window steel retaining frame

TDI.1

The spacer between two outer rings

Pillar type steel cage (perforated roller) suitable for higher loads

TDIE

The spacer between two outer rings

Window steel retaining frame

Extend the inner circle at both ends

The extended part has been ground to serve as the mating end face for the sealing lip

TDIT

The spacer between two outer rings

Conical hole, taper 1:12

Window steel retaining frame

TDIS

Large contact angle α

Suitable for applications where high axial and radial loads occur simultaneously

The spacer between two outer rings

Window steel retaining frame

Used in rolling mill applications with loose fit on the roll neck, and only capable of bearing pure axial loads

There are one or more positioning slots (grooves) on one or both sides of the inner ring to prevent it from rotating on the base

Depending on the purpose, the bearing can have or not have a spacer between the two outer rings

TDIS.1

Large contact angle α

Suitable for applications where high axial and radial loads occur simultaneously

The spacer between two outer rings

Pillar type steel cage (perforated roller) suitable for higher loads

TDIS.2

There is a self holding unit with a retaining sleeve on the outer ring

The outer ring is pressed into the liner

The deformation of the outer ring caused by axial overload is significantly improved

Therefore, the pressure distribution in rolling contact is more favorable, thereby extending the service life of the bearing

The axial internal clearance depends on the sleeve

No need to preload with springs

Large contact angle α

Suitable for applications where high axial and radial loads occur simultaneously

Simplified and economical design facilitates installation, disassembly, and maintenance inspection procedures