Description

IMCB can provide four row tapered roller bearings in TQO and TQI model series, with specific types as follows:

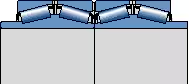

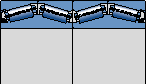

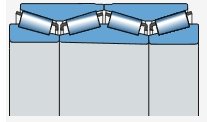

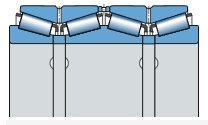

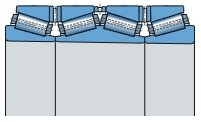

TQO designed bearings (face-to-face configuration):

Open or sealed

With cylindrical or conical holes

Extended with or without inner ring on both sides

Bearing with or without spiral groove inside

Basic design or IMCB Explorer bearings

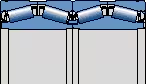

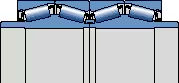

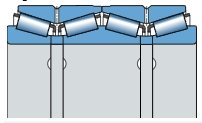

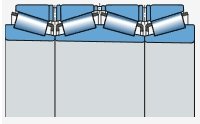

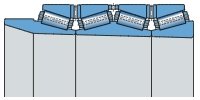

TQI designed bearings (back-to-back configuration):

With cylindrical or conical holes

Extension with or without inner ring on one side

TQO type bearings

TQO type bearings have two pairs of tapered rollers and cage components. Double row rollers are configured face-to-face for each pair. Because TQO is the most widely used four row tapered roller bearing design, IMCB can offer multiple types of this model, such as:

Design form characteristics

TQON

Two double row inner rings

Four single row outer rings

No spacer ring

Window steel retaining frame

TQO

Two double row inner rings

One double row and two single row outer rings

There are spacers between the outer rings and spacers between the inner rings

Window steel retaining frame

TQON.1

Two double row inner rings

Four single row outer rings

No spacer ring

Pin type steel cage (perforated roller)

TQO.1

Two double row inner rings

One double row and two single row outer rings

There are spacers between the outer rings and spacers between the inner rings

Pin type steel cage (perforated roller)

TQOEN

Two double row inner rings, with one side lengthened

The extended inner rings on both sides of the bearing are designed as opposite surfaces for radial shaft sealing

Four single row outer rings

No spacer ring

Window steel retaining frame

TQOE

Two double row inner rings, with one side lengthened

The extended inner rings on both sides of the bearing are designed as opposite surfaces for radial shaft sealing

One double row and two single row outer rings

There are spacers between the outer rings and spacers between the inner rings

Window steel retaining frame

TQOT

Two double row inner rings

One double row and two single row outer rings

There is a spacer between the outer rings

Window steel retaining frame

Conical hole, taper 1:12

If the roll neck requires an interference fit

TQOSN

Two double row inner rings

Four single row outer rings

No spacer ring

Window steel retaining frame

Sealed on both sides

TQOSNP

Two double row inner rings

Four single row outer rings

There is a spacer between the two inner rings and the two middle outer rings

Window steel retaining frame

Sealed on both sides

TQOS

Two double row inner rings

One double row and two single row outer rings

There are spacers between the outer rings and spacers between the inner rings

Window steel retaining frame

Sealed on both sides

TQOSN.1

Two double row inner rings

Four single row outer rings

No spacer ring

Pin type steel cage (perforated roller)

Sealed on both sides

TQOESN

Two double row inner rings, with one side lengthened

The extended inner rings on both sides of the bearing are designed as opposite surfaces for radial shaft sealing

Four single row outer rings

No spacer ring

Window steel retaining frame

Sealed on both sides

TQOES

Two double row inner rings, with one side lengthened

The extended inner rings on both sides of the bearing are designed as opposite surfaces for radial shaft sealing

One double row and two single row outer rings

There are spacers between the outer rings and spacers between the inner rings

Window steel retaining frame

Sealed on both sides

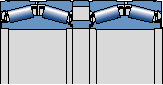

TQI type bearings

TQI type bearings have two pairs of tapered rollers and cage components. Each pair of double row rollers is configured back-to-back. This type of bearing provides a relatively rigid bearing configuration and can withstand overturning moments. In this application, bearings are generally installed on the roll neck with interference fit, so they often have tapered holes.

TQI type bearings are also used for the vertical rollers of universal rolling mills. In this case, a bearing with a cylindrical hole is required because the inner ring has a clearance fit on its journal and the outer ring is installed in the bearing seat in an interference fit manner.

Example of TQI design form:

Design form characteristics

TQIN

One double row and two single row inner rings

Two double row outer rings

No spacer ring

Window steel retaining frame

TQINT

One double row and two single row inner rings

Two double row outer rings

No spacer ring

Window steel retaining frame

Conical hole, taper 1:12 or 1:30

TQI

One double row and two single row inner rings

Two double row outer rings

There is a spacer between the outer rings

Two spacers between the inner rings

Window steel retaining frame

TQI.1

One double row and two single row inner rings

Two double row outer rings

There is a spacer between the outer rings

Two spacers between the inner rings

Pin type steel cage (perforated roller)

TQI.2

One double row and two single row inner rings

Two double row outer rings

Two spacers between the inner rings

Window steel retaining frame

TQIT

One double row and two single row inner rings

Four single row outer rings

Three spacers between the outer rings

Window steel retaining frame

Conical hole, taper 1:12 or 1:30

If the roll neck requires an interference fit

TQIT.1

One double row and two single row inner rings

Four single row outer rings

Three spacers between the outer rings

Pin type steel cage (perforated roller)

Conical hole, taper 1:12 or 1:30

If the roll neck requires an interference fit

TQITE

One double row and two single row inner rings

The inner ring is lengthened on one side

Four single row outer rings

Three spacers between the outer rings

Window steel retaining frame

Conical hole, taper 1:12 or 1:30

If the roll neck requires an interference fit

TQITE.1

One double row and two single row inner rings

The inner ring is lengthened on one side

Four single row outer rings

Three spacers between the outer rings

Pin type steel cage (perforated roller)

Conical hole, taper 1:12 or 1:30

If the roll neck requires an interference fit

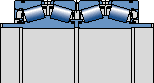

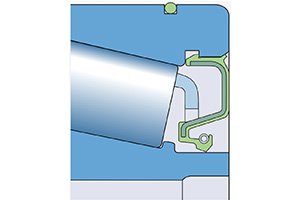

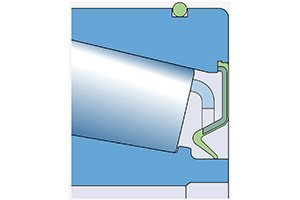

sealed bearing

Compared with open type bearings, it has the following general advantages:

Extend the service life of bearings

Improve reliability

Reduce maintenance

Reduced consumption of lubricating grease (up to 90%)

reduced environmental impacts

Reduce the pollution of excess lubricating grease on the grinding emulsion to improve the steel rolling process and product quality

It is the preferred solution for rolling mills

It is a simple alternative to open type bearings, as they have the same external dimensions and even the same load-bearing capacity depending on the sealing design (IMCB Explorer bearings)

There are grooves with O-rings on the outer surface of the bearing to prevent any contaminants from entering the position between the outer ring and the bearing seat

One of the following seals is installed on both sides:

Standard fluororubber sealing design

Standard hydrogenated nitrile rubber seal design for IMCB Explorer bearings

Upgraded hydrogenated nitrile rubber seal design for IMCB Explorer bearings

Table 1 provides an overview of sealing design.

Identify with model suffix S