Description

IMCB offers two designs of needle roller thrust bearings:

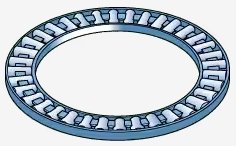

AXK series needle roller cage thrust assembly

Needle roller thrust bearing with guiding edge, AXW series

In applications where adjacent machine component surfaces cannot be used as raceways, components can be used in conjunction with different series of bearing races (bearing races).

Needle roller holder thrust assembly

AXK series needle roller cage thrust assembly :

Suitable for 4 ≤ d ≤ 160 mm

Can only withstand unidirectional axial loads

In applications where adjacent components cannot be used as raceways, components can be used in conjunction with LS, AS, GS 811, or WS 811 series bearing races (bearing races)

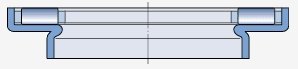

Bidirectional bearings

Capable of withstanding axial loads in two directions

It can be composed of two needle rollers and a thrust assembly with a cage, as well as a bearing ring with an intermediate ring

Depending on the design, the middle ring can be a shaft guide or a bearing seat guide.

The hardness and surface finish of the intermediate ring must be the same as those of the bearing race. IMCB does not provide intermediate rings, but can provide material technical parameters and dimensional data upon request.

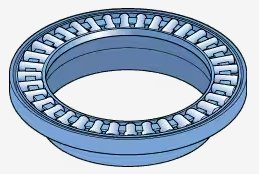

Needle roller thrust bearing with guiding edge

AXW series needle roller thrust bearing with guiding edge  and

and

Suitable for 10 ≤ d ≤ 50 mm

Can only withstand unidirectional axial loads

Composed of a needle roller holder thrust assembly and a thrust seat ring with a guide stop edge

The blocking edge facilitates installation and accurately achieves radial positioning of the seat ring (Figure 6 and Figure 7).

Combination arrangement of needle roller bearings

In order to withstand both radial and axial loads, the AXW series needle roller thrust bearings can be used in conjunction with the following radial needle roller bearings:

Closed or open stamped outer ring needle roller bearings .

Needle roller bearing with machined ring

These arrangements provide cost-effective and compact solutions for joint loads.

bearing ring

In applications where adjacent machine components cannot be used as raceways, bearing rings are required.

The applicable rings can be found in the product list, but due to the numerous different combinations available, they must be ordered separately.

The following series can be used in conjunction with needle roller thrust bearings:

LS series universal ring

Made of hardened carbon chromium bearing steel

They can be used as shaft rings or race rings for AXK series needle roller thrust bearings.

Can be used as a shaft ring for AXW series bearings

Suitable for 6 ≤ d ≤ 160 mm

The surface of the raceway is ground, while other surfaces are turned

Suitable for working conditions where the seat ring does not require precise centering or low-speed conditions

The opposite side of the chamfer on the collar is the raceway surface, which should face the needle roller

AS series universal thin ring

1 mm thick

Made of spring steel and subjected to hardening treatment

Can be used as a shaft ring or seat ring for AXK series needle roller thrust bearings.

Can be used as a shaft ring for AXW series bearings

Suitable for 4 ≤ d ≤ 160 mm

If adjacent equipment components have not been hardened, but have sufficient rigidity and meet general requirements for form and position tolerances, they can be used as an economical bearing solution.

Both sides of the collar have been polished and can be used as a raceway.

811 series shaft (prefix WS) and bearing race (prefix GS)

Mainly used for cylindrical roller cage components

It can also be combined with needle rollers and cage thrust components

Used in high-speed applications that require precise alignment of bearing seat rings

For more information about the 811 series race, please refer to the cylindrical roller thrust bearing.