Description

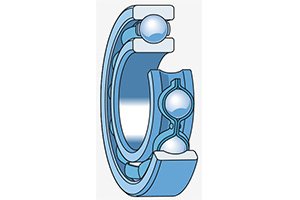

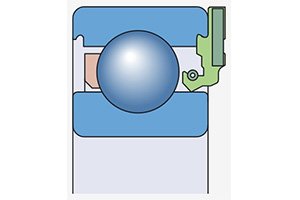

Single row deep groove ball bearings are the most widely used type of bearing .

.

Provide closed (with sealed or dust cover) or open design. Open type bearings can also be equipped with seals or dust covers, with grooves on the outer ring side .

.

The IMCB imperial bearings in the EE (B), RLS, and RMS series are products intended for the aftermarket, therefore, IMCB recommends not using these bearings for newly designed bearing configurations.

For bearing selection and technical details, please refer to the product table.

IMCB can also provide bearings with tapered holes. For detailed information, please contact IMCB.

closed bearing

For the selection guide of different sealing types under various operating conditions, please refer to Table 1. However, these guidelines cannot replace the testing of dust covers or seals in practical applications. For more information, please refer to the built-in seal.

Sealed installation in the outer ring groove, in close contact with the groove, and will not cause deformation of the outer ring. Sealing types include:

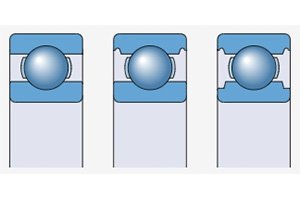

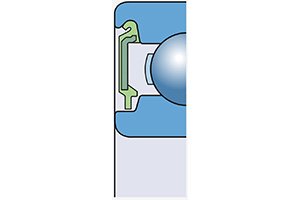

dust cover

Represented by the suffix Z of the model

Mainly used in the working condition of inner ring rotation

Installed in the outer ring and forming a narrow gap with the inner ring

Made of stamped steel

Standard configuration includes a flanged hole in the dust cover  , while some sizes do not have a flanged hole

, while some sizes do not have a flanged hole

Prevent dust and debris without friction loss

non-contact seal

Represented by the model suffix RZ

Has better sealing effect than dust cover

Same operating speed as the dust cover

Create an extremely narrow gap with the inner ring shoulder

Made of nitrile rubber reinforced with strip steel skeleton (oil resistant and wear-resistant)

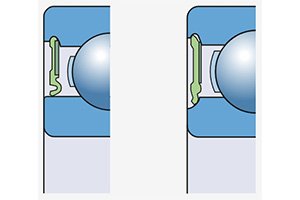

Low friction seal

Represented by the model suffix RSL

Has better sealing effect than non-contact sealing

Made of nitrile rubber reinforced with strip steel skeleton (oil resistant and wear-resistant)

Same operating speed as the dust cover

Almost no contact with the groove on the inner ring shoulder

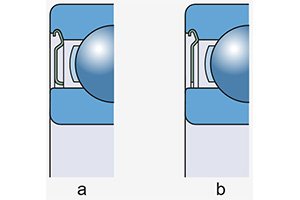

Two designs of 60, 62, and 63 series bearings are available, depending on the size

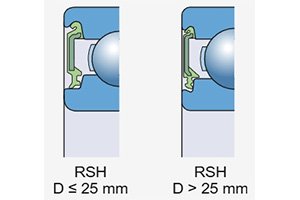

Contact seal

Represent with model suffix RSH, RSH2, RS1 or RS2

Made of reinforced steel frame

Nitrile rubber

Fluororubber (model suffix RS2 or RSH2, available upon request)

The bearing with suffix VA947 is equipped with a seal made of food compatible blue nitrile rubber.

The materials have been approved by the US Food and Drug Administration and the European Commission. The approval from the US Food and Drug Administration is based on Title 21, Section 177.2600 of the Federal Regulations: “Reusable Rubber Articles” for use in contact with foods containing water or oil. The approval by the European Commission is based on the overall migration requirements for three types of food contact materials in Recommendation XXI of the German Federal Institute for Risk Assessment.

Different designs can be provided based on the bearings used:

Two RSH designs are available for the 60, 62, and 63 series bearings  , depending on the size

, depending on the size

RS1 is designed to seal tightly against the inner ring shoulder or inner ring side groove ; The relevant design is determined by the product table size d1 or d2.

; The relevant design is determined by the product table size d1 or d2.

For products with model suffixes RS and JEM, use the same sealing design (RSH or RS1) as the bearings without the JEM suffix.

warn

If the seal made of fluororubber is exposed to open flames or high temperatures above 300 ° C (570 ° F), it will endanger health and the environment! Even after cooling, it still poses a hazard.

Please read and follow the safety precautions in the warning section.

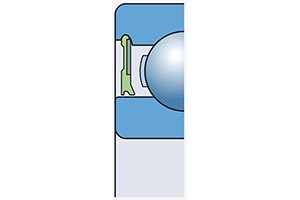

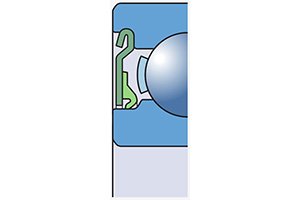

Contact sealing for high pollution environments

Represented by the model suffix RSF  .

.

Made of the following materials:

Stamped steel dust cover forming a narrow gap with the inner ring

Nitrile based rubber sealing lip tightly attached to the precision grinding mating surface of the inner ring groove

Designed to prevent liquid and solid pollutants.

ICOS oil sealed bearing unit

Usually used in applications with sealing solutions that exceed standard sealing capabilities, i.e. oil retention sealing requirements

Compared with bearings that use external sealing, it has the following advantages:

Less axial space required

Simplified installation

The inner ring shoulder can serve as a sealing mating surface, thus avoiding the expensive cost of shaft machining

Including a 62 series deep groove ball bearing and an IMCB WAVE seal :

:

Single lip radial shaft seal with spring compression on one side

Made of nitrile rubber

The maximum speed listed in the product table is based on the allowable circumferential speed of the seal (14 m/s)