Description

IMCB spherical roller bearings are the most comprehensive series in the market. Standard products include:

CC, CA, and E-type bearings

sealed bearing

Bearings for special applications

IMCB spherical roller bearings belong to IMCB Explorer bearings, except for bearings suitable for continuous casting applications. Almost all bearings can choose tapered holes. According to the bearing series, conical holes have:

The taper is 1:12 (model suffix K)

The taper is 1:30 (model suffix K30)

If you need dimensions and types not listed in the product table, please contact IMCB.

CC, CA, and E-type bearings

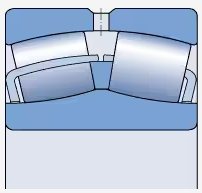

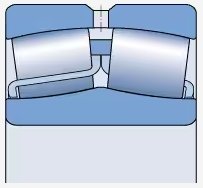

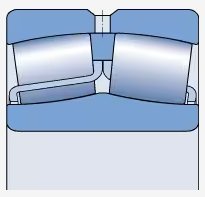

CC type bearing

Equipped with two window type stamped steel retainers, an inner ring without a stopper, and a floating guide ring guided by the inner ring

Use the suffix C or CC to indicate the model in the product table

The internal optimization design of large bearings with model suffix EC or ECC in the product table can improve their load-bearing capacity

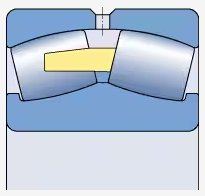

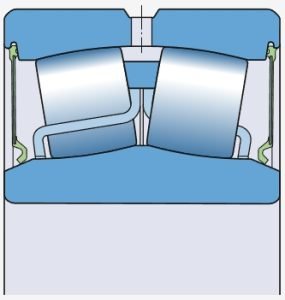

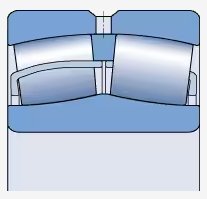

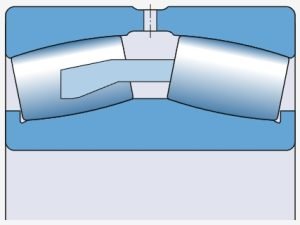

CA type bearing

Equipped with a fork type machined brass holder, an inner ring with positioning ribs on both sides, and a floating guide ring guided by the inner ring

The retaining edge on the inner ring is used to keep the rollers from tilting when rotating the bearing during installation or maintenance. This design is not intended to guide the rollers or bear any axial loads.

Indicate the model suffix CA in the product table

The internal optimization design of large bearings with the suffix ECA in the product table can improve their load-bearing capacity

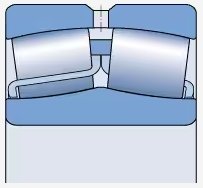

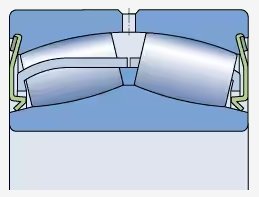

E-type bearings

Equipped with two window type stamped steel holders, an inner ring without a stopper, and a floating guide ring guided by the inner ring (d ≤ 65 mm) or holder (d>65 mm)

Use the suffix E to indicate the model in the product table

Featuring optimized internal design to enhance load-bearing capacity

Holder

For more information on the applicability of the cage, please refer to the cage.

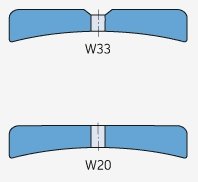

Lubrication groove and lubrication hole

CC and CA type bearings have an annular lubrication groove and three lubrication holes (model suffix W33) or only three lubrication holes (model suffix W20) on the outer surface of the outer ring.

The standard configuration of the E-type bearing

is an annular lubrication groove and three lubrication holes inside the groove. This feature will not be labeled in the bearing model (without suffix).

Outer ring with sealing groove

Open type bearings can also be equipped with seals, and there are usually grooves on the outer ring side.

sealed bearing

Having the same characteristics as open spherical roller bearings

Standard configuration includes cylindrical holes

Internally filled with lubricating grease, cannot be cleaned

Except for bearings with model suffix W, there is an annular lubrication groove and three lubrication holes on the outer surface of the outer ring

One or both sides of the bearing are equipped with contact seals, made of one of the following materials:

Nitrile rubber reinforced with steel frame (model suffix CS or RS)

Hydrogenated nitrile rubber reinforced with steel frame (model suffix CS5 or RS5)

Fluorine rubber reinforced with steel frame (model suffix CS2)

Steel frame with G-ECOPUR sealing lip (model suffix CS6)

Sealed and fixed in the groove of the outer ring, with the lip tightly attached to the inner ring

In larger bearings, the seal is fixed in the groove of the outer ring by a snap ring.

The lubrication cycle of sealed bearings is almost the same as the bearing life, and maintenance free (the grease life of sealed bearings) can be achieved. The bearing is filled with one of the following lubricating greases:

model

Description of suffix lubricating grease

VT143 LGEP 2 Extreme Pressure Additive

GEA LGEV 2 Ultra high viscosity grease containing solid lubricant

GEM LGHB 2 Heavy Duty, High Temperature

GFP LGFQ 2 Heavy Duty, Food Grade

GLE LGWM 2 Heavy Duty, Wide Temperature Range

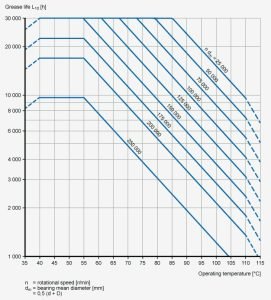

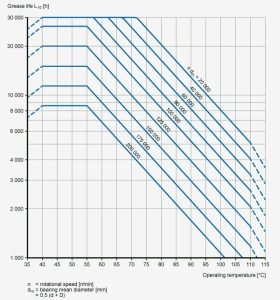

Lubricating grease life of sealed bearings

The grease life of sealed bearings is represented by L10, which means that at the end of this time period, 90% of the bearings can still receive reliable lubrication, and it depends on the load, operating temperature, and speed. If the bearing is filled with standard IMCB LGEP 2 grease (model suffix VT143), the grease life can be checked from the following chart:

Light Load (P ≤ 0.067 C)

Light Load (P ≤ 0.067 C)

Normal Load (P ≤ 0.125 C)

Normal Load (P ≤ 0.125 C)

The lifespan of the lubricating grease in the chart is effective under the following operating conditions:

horizontal axis

Inner circle rotation

The working temperature is within the green temperature range of the grease traffic light concept

Non mobile devices

Low vibration level

Load ratio Fa/Fr ≤ e (product table)

Below the limit speed (product table) and the speed limits listed in

For other working conditions, the grease life can be estimated by multiplying the lubrication cycle of the open bearing (estimated grease lubrication cycle) by a coefficient of 2.7.

Supplementary lubrication of sealed bearings

When the required bearing service life is longer than the grease service life, the bearing needs to be lubricated again. The formula below can be used to calculate the amount of supplementary lubricating grease required for sealed bearings

Gp = 0,0015 D B

of which

Gp oil content [g]

D bearing outer diameter [mm]

B bearing width [mm]

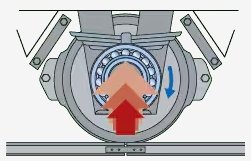

When supplementing lubrication, lubricating grease should be slowly injected through the lubrication holes on the outer ring, and it is best to rotate the bearing at the same time to avoid damaging the seal. IMCB recommends using the same lubricating grease as the initial filling for supplementary lubrication.

warn

If the seal made of fluororubber is exposed to open flames or high temperatures above 300 ° C (570 ° F), it will pose a threat to health and the environment! Even after cooling, it still poses a hazard.

Please read and follow the safety precautions in the warning section.

Bearings for vibration machinery

223 product series available

Can provide cylindrical or conical hole types

The standard internal radial clearance is C4

There is an annular lubrication groove on the outer surface of the outer ring, with three lubrication holes inside the groove

Manufacture according to one of the following designs:

The E/VA405 bearing (Figure 7) is equipped with two surface hardened window type stamped steel retainers, an inner ring without a stopper, and a floating guide ring guided by the inner ring or retainer.

The EJA/VA405 and CCJA/W33VA405 bearings and

and are equipped with two surface hardened window type stamped steel retainers, an inner ring without a stop edge, and a floating guide ring guided by the outer ring raceway.

are equipped with two surface hardened window type stamped steel retainers, an inner ring without a stop edge, and a floating guide ring guided by the outer ring raceway.

We can provide bearings with cylindrical holes coated with PTFE (model suffix VA406) to prevent creep corrosion between the shaft and the inner hole of the bearing. It is suitable for floating end bearings with rotating outer rings to adapt to shaft expansion caused by heating. Therefore, when using bearings with this design, the shaft does not require special heat treatment or coating.

warn

If the PTFE coating is exposed to open flames or high temperatures above 300 ° C (570 ° F), it will pose a threat to health and the environment! Even after cooling, it still poses a hazard.

Please read and follow the safety precautions in the warning section.

acceleration

The application in vibration scenarios can cause acceleration in the rollers and cage of the bearing. This adds additional requirements to the bearing design. The IMCB spherical roller bearings used for vibration equipment can withstand much higher acceleration than standard bearings of the same size. The allowable acceleration depends on the lubricant used and the mode of acceleration.

The rotational load of the outer ring and the acceleration of circular motion will act on the bearing simultaneously, or the angular acceleration will change internally due to a sharp change in speed. These accelerations will cause the unloaded rollers to generate rotational loads on the cage.

For example: vibrating screen  exciter, planetary gear, and other conventional bearing configurations that are in rapid start-up or rapid speed changes.

exciter, planetary gear, and other conventional bearing configurations that are in rapid start-up or rapid speed changes.

Bearings will bear impact loads, which generate linear acceleration along a fixed radial direction, causing unloaded rollers to “strike” the cage, such as train wheels rolling over track joints, resulting in acceleration

When the roller of the road roller vibrates on a hard road surface, it will simultaneously withstand both mode 1 and mode 2 accelerations. The allowable acceleration is listed in the product table and is applicable to oil lubricated bearings. These values are expressed as multiples of g, where g represents the gravitational acceleration (g=9.81 m/s2).

System solution for vibrating screen

In addition to a single bearing applied to vibrating screens, IMCB has also developed a fault monitoring and bearing configuration system that can improve the performance of vibration equipment, reduce maintenance, and monitor the operating status of the equipment.

Bearings suitable for wind power applications

Can provide 240 series products (d ≥ 530 mm)

Specially designed for wind turbine spindles

Featuring an optimized internal geometric structure, equipped with large-diameter rollers and a larger contact angle, the axial load-bearing capacity of the bearing has been improved

Cast iron cage with rolling element guidance improves the robustness of the cage

Without floating guide ring

There is a wide annular lubrication groove on the outer surface of the outer ring and six lubrication holes inside the groove

Use the suffix BC to indicate the model in the product table

Bearings suitable for high-speed applications

Has a maximum speed 50% higher than standard bearings

We can provide special forms of bearings for the 223, 232, 240, and 241 series

Satisfied the market demand for multi megawatt industrial gearboxes

Use the model suffix VA991 in the product table to indicate

Bearings suitable for continuous casting machine applications

Specially designed to cope with extreme temperatures, high loads, low speeds, and pollution in continuous casting machine applications

Through patented heat treatment process, subsurface stress is generated, thereby reducing the risk of crack propagation during operation

Provide larger internal space to store more lubricants

Use the model suffix VA9B1 in the product table to indicate

Bearings suitable for food and beverage applications

Equipped with low friction contact seals, it has excellent waterproof and anti solid pollutant performance

Lubricated with high-performance NSF H1 grade grease and certified by Islamic and Jewish food standards

Complies with the recommendations of the US Food and Drug Administration (FDA) and the European Community (EC)

Compared to open type bearings, its service life is on average three times longer

Use the model suffix VA944 in the product table to indicate